Solve the problem of belt slippage and corrosion: Comprehensive Guide to Performance Differences and Selection of Polyester, Ceramic Lagging and Rubber Pulley

Transmission Pulley is the power source of the Conveyor Belt. The friction coefficient, wear resistance and peeling strength of its surface coating material directly determine the power transmission efficiency of the system. In the face of harsh working conditions such as moisture, dust, high load or strong corrosion, how to specifically select polyester, ceramic or rubber lagging solutions is the key to ensuring stable operation of the system.

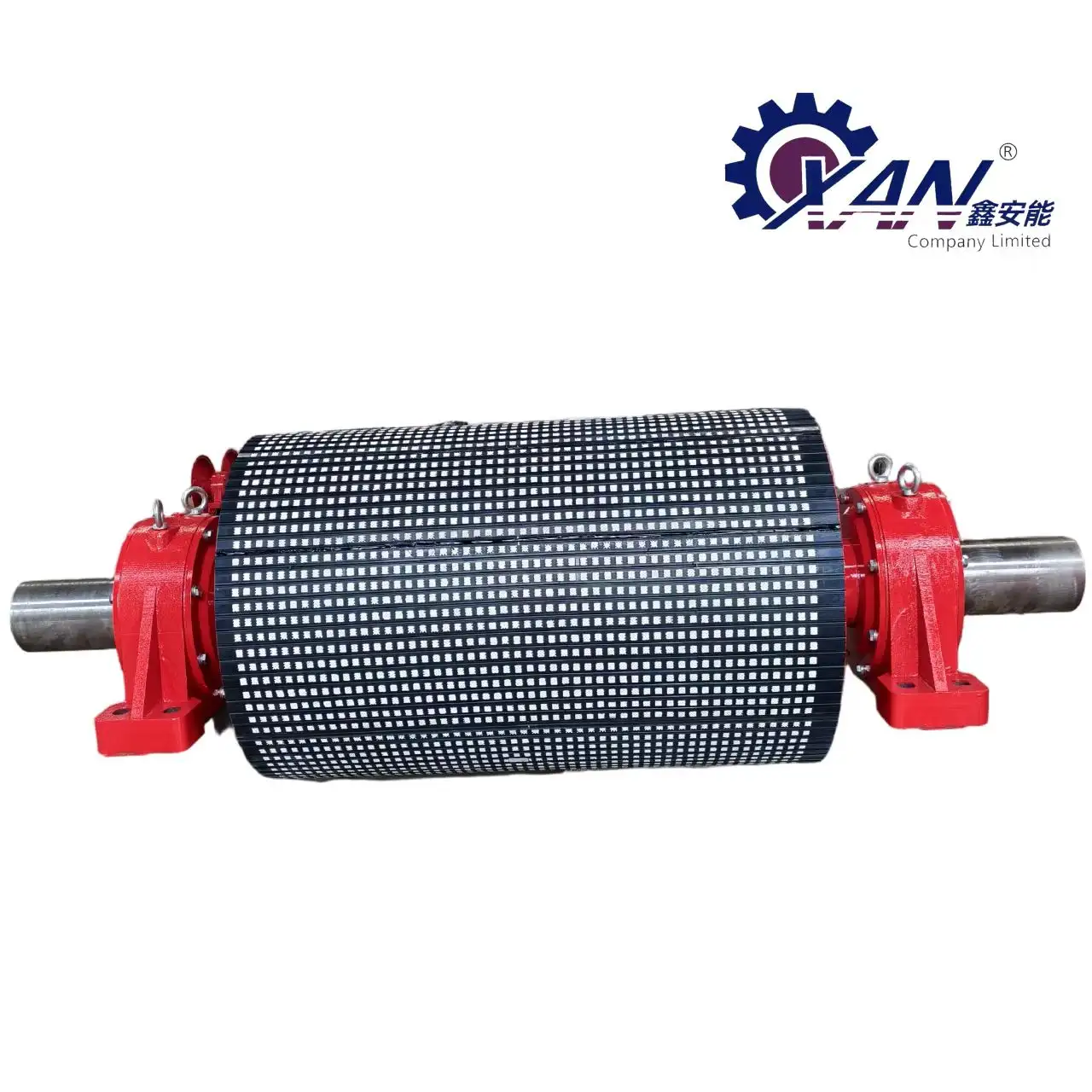

High wear conditions 95 Alumina Ceramic Rubber Pulley

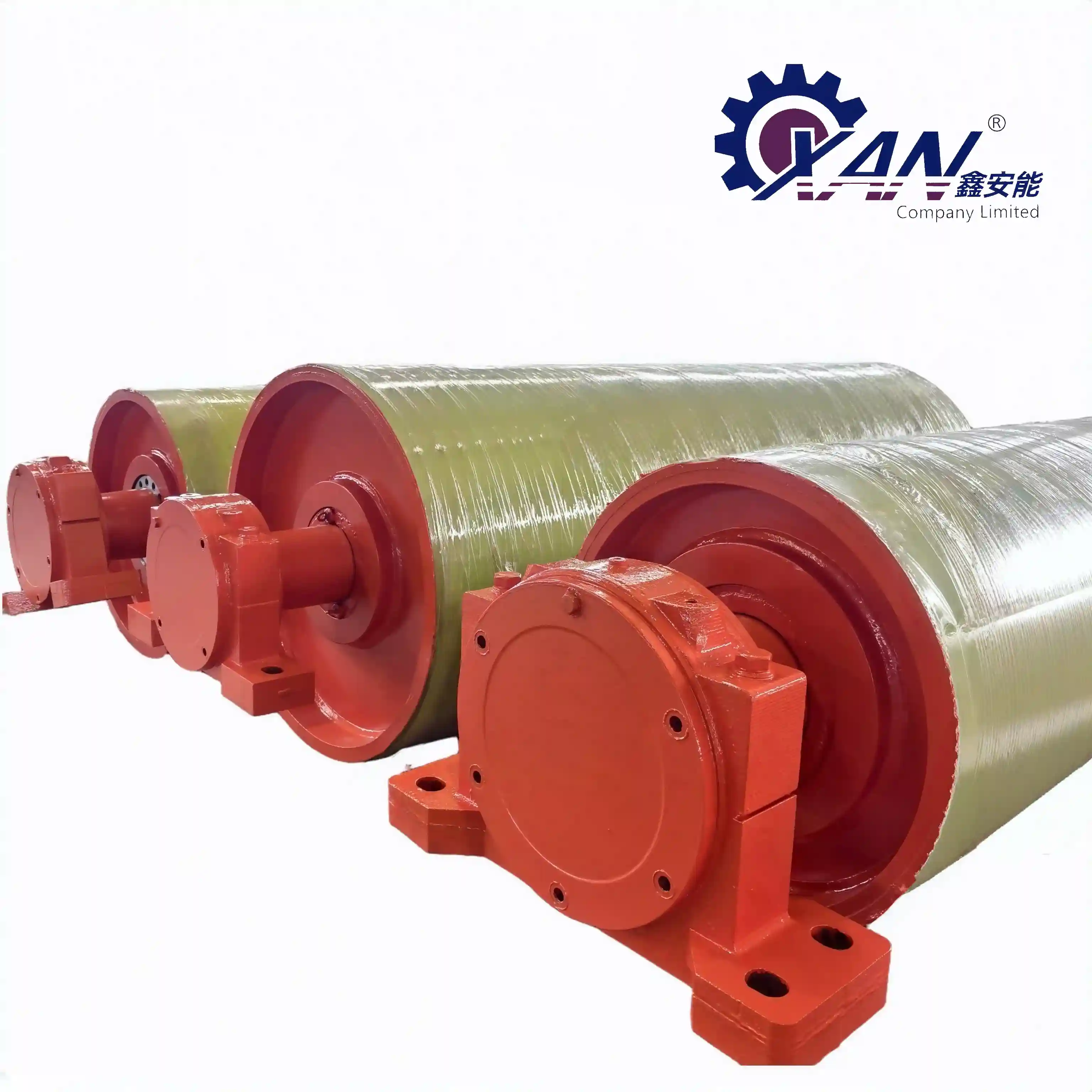

High-performance polyester Pulley for extreme corrosion-resistant environments

First of all, Ceramic Rubber Pulley is the "ultimate solution" to solve the problem of heavy load and slippage. Xinanneng uses an alumina ceramic block with a purity of up to 95%, which is embedded into a wear-resistant rubber matrix through a cold vulcanization process. The raised particles on the ceramic surface can generate huge friction between the belt and Pulley. Even in the case of extreme humidity, rain or accumulation of sticky materials, the belt can be tightly held to completely eliminate slipping. In addition, the extremely high hardness of ceramics makes its service life usually 3-5 times that of traditional rubber pulleys, significantly reducing long-term downtime and maintenance costs.

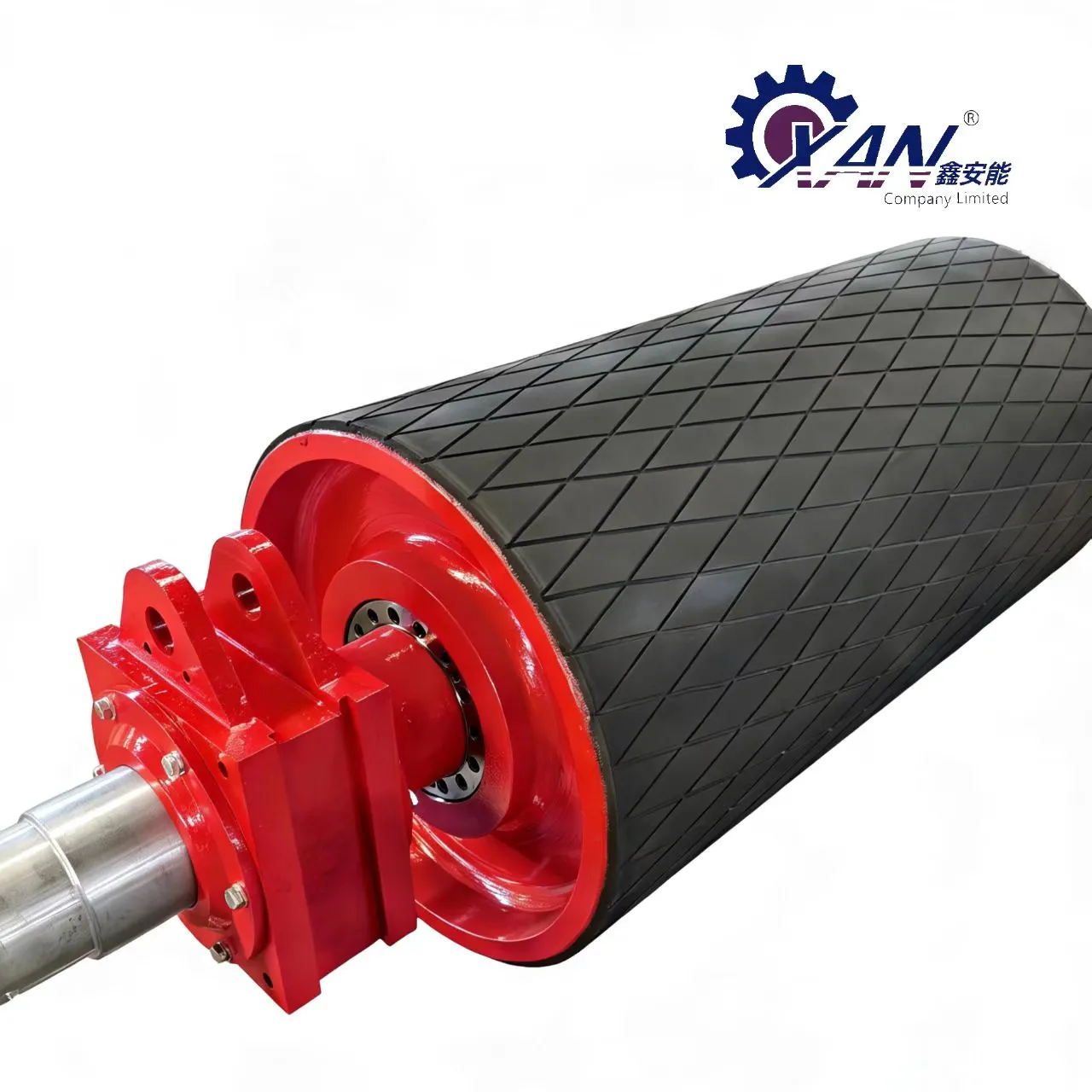

Heavy transmission drive Pulley structure display

High-performance polyester Pulley (Polyester Pulley) has demonstrated excellent defense properties in chemical industry, fertilizer plants or coastal high-salt spray environments. Unlike traditional metal pulleys, which are prone to rust and chemical reactions, polyester materials have natural chemical inertness and strong acid and alkali resistance. Its surface is extremely smooth and has self-lubricating properties, which can effectively prevent materials from scaling on the Pulley surface, thereby avoiding belt deviation caused by uneven wear. For special working conditions that pursue the ultimate anti-corrosion life, polyester Pulley is currently the best choice.

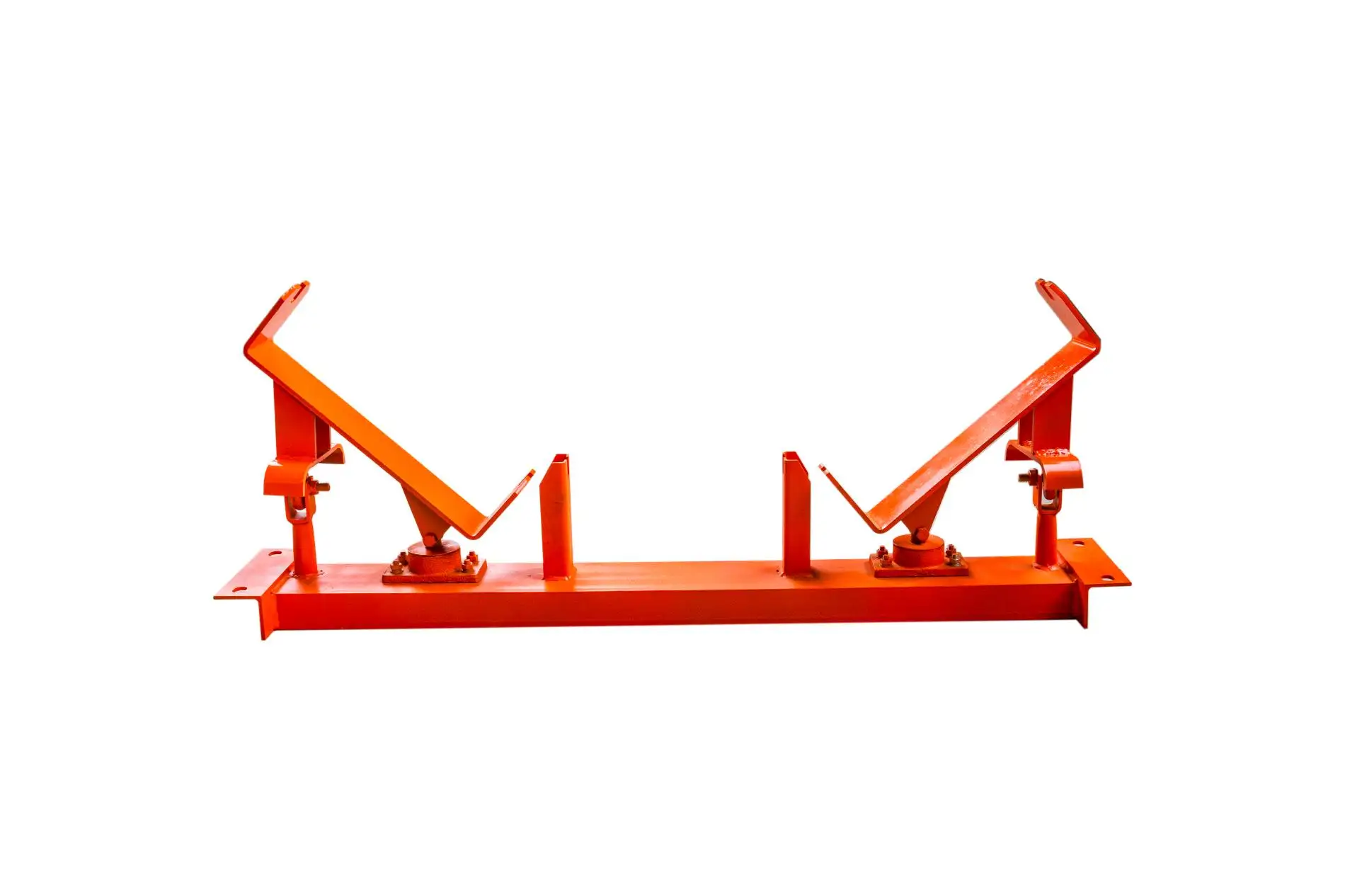

Hot vulcanized rubber lagging process details

In normal working conditions and scenarios that pursue high cost performance, hot vulcanized rubber lagging is still the mainstream choice. By covering the surface of Pulley body with high-quality natural rubber or synthetic rubber and undergoing high-temperature and high-pressure vulcanization treatment, the rubber layer and the cylinder form a strong physical bond. Xinanneng provides a variety of groove designs such as diamond and herringbone, aiming to improve Pulley's drainage and mud discharge capabilities, and increase the grip of the contact area. This solution has mature technology and moderate cost, and can meet the daily transportation needs of most mines and factories.

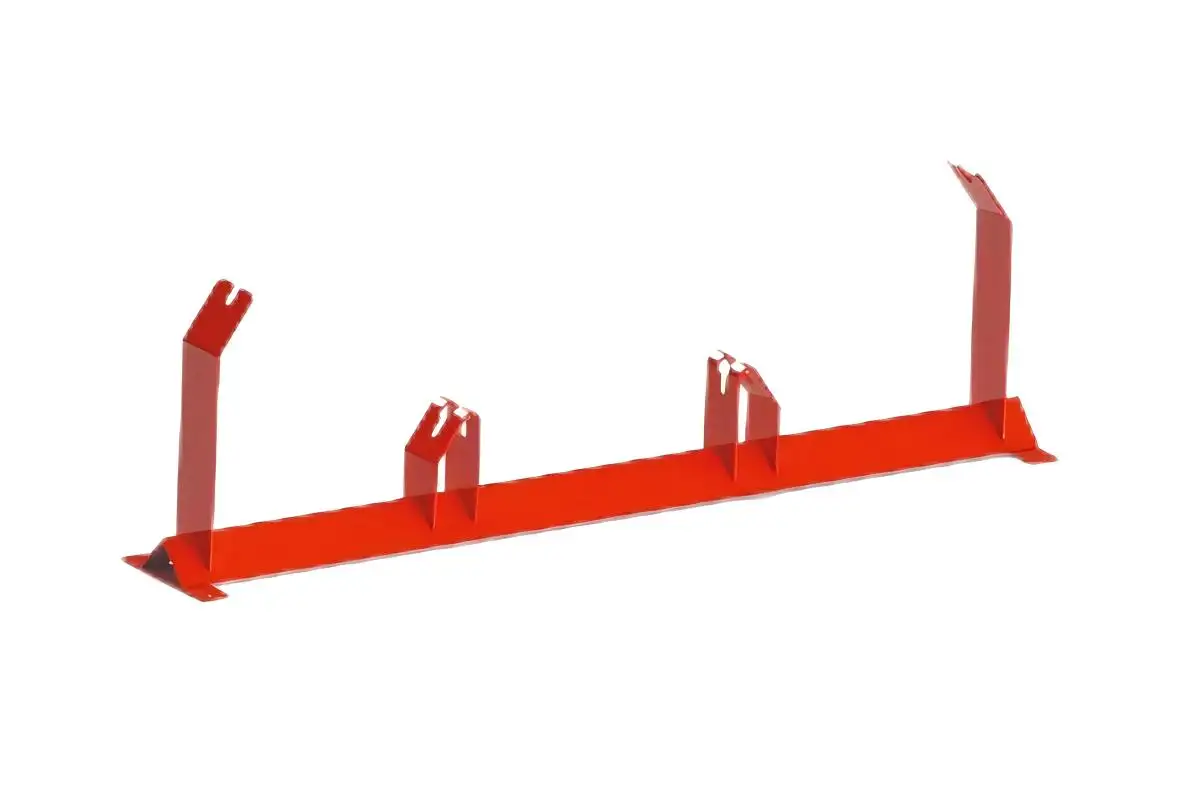

High Tension Turn About Pulley Solution

In addition to the rubberized material, Pulley’s structural design cannot be ignored. The Transmission Pulley needs to withstand huge torque and radial pressure, so Xinanneng uses a reinforced cylinder structure and large-size spherical roller bearings. For Turn About Pulley, which changes the direction of the belt, it focuses on the fatigue resistance of the shaft head and the rotation accuracy of the cylinder. Through advanced dynamic balance calibration, we ensure that Pulley vibrates minimally under high-speed operation, thereby protecting the structural safety of the entire machine frame.

In summary, ceramic encapsulation pursues "grip and longevity", polyester Pulley focuses on "extreme anti-corrosion", and rubber encapsulation balances "performance and cost". Xinanneng has a full range of manufacturing capabilities and can provide customized Pulley combination solutions based on your actual working conditions (such as belt speed, tension, material characteristics, and environmental temperature and humidity) to help the conveyor system operate efficiently and long-term.