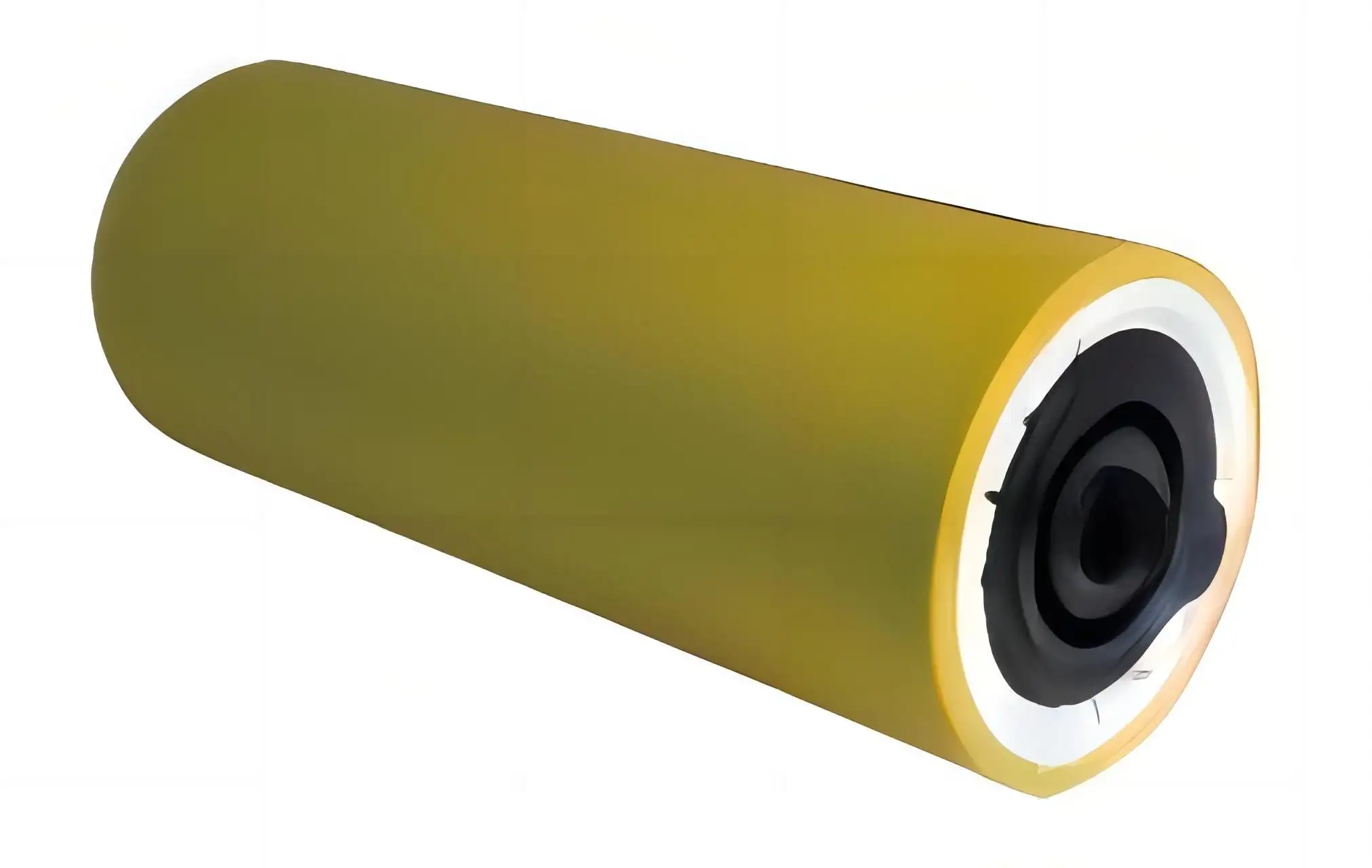

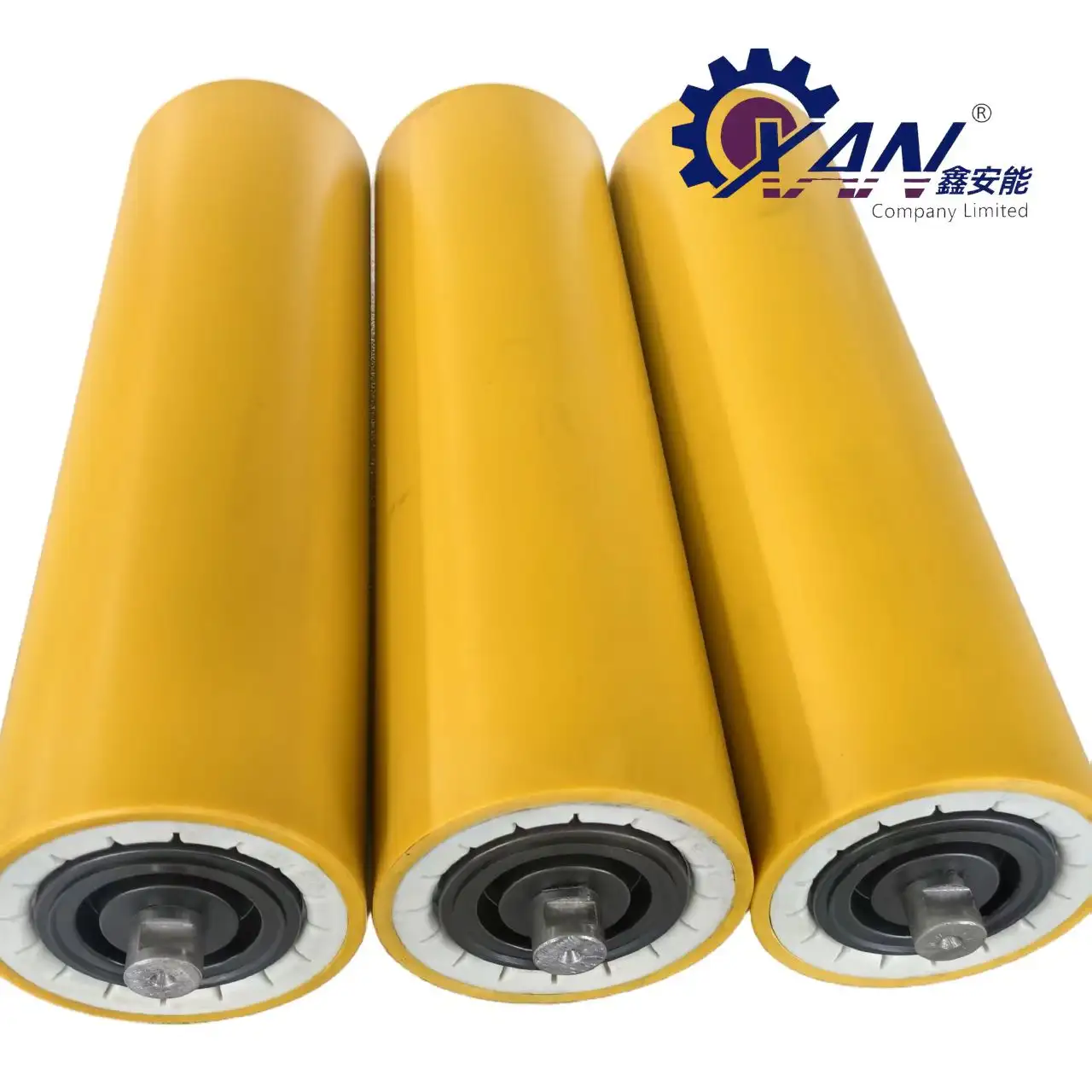

HDPE Idler

Polymer material·Lightweight and corrosion-resistant·Low noise and energy saving

Hubei Xinanneng Conveyor Equipment Co., Ltd.'s HDPE Idler (high-density polyethylene Idler) is a new generation of energy-saving, noise-reducing, and environmentally friendly conveyor components. The roller body is made of high molecular polyethylene material, which has significant advantages such as good self-lubrication, low friction coefficient, corrosion resistance, antistatic and non-water absorption. Compared with traditional steel Idler, its weight is reduced by about 50%, which can significantly reduce the starting load and operating energy consumption of the conveyor.

In environments with corrosive gases such as chemical industries, ports, and fertilizer plants, HDPE Idler exhibits excellent resistance to chemical erosion, completely solving the problem that steel Idler is prone to rust and rot. In addition, the polymer material has excellent shock-absorbing properties, which can significantly reduce operating noise and provide a more comfortable working environment for on-site operators. Its surface is extremely smooth, materials are not easy to adhere, and it can effectively protect the belt from scratches. It is an ideal energy-saving component for building modern green mines and fine chemical plants.

Discover more - Made in China online store

Online display center: https://xanconveyor.en.made-in-china.com/