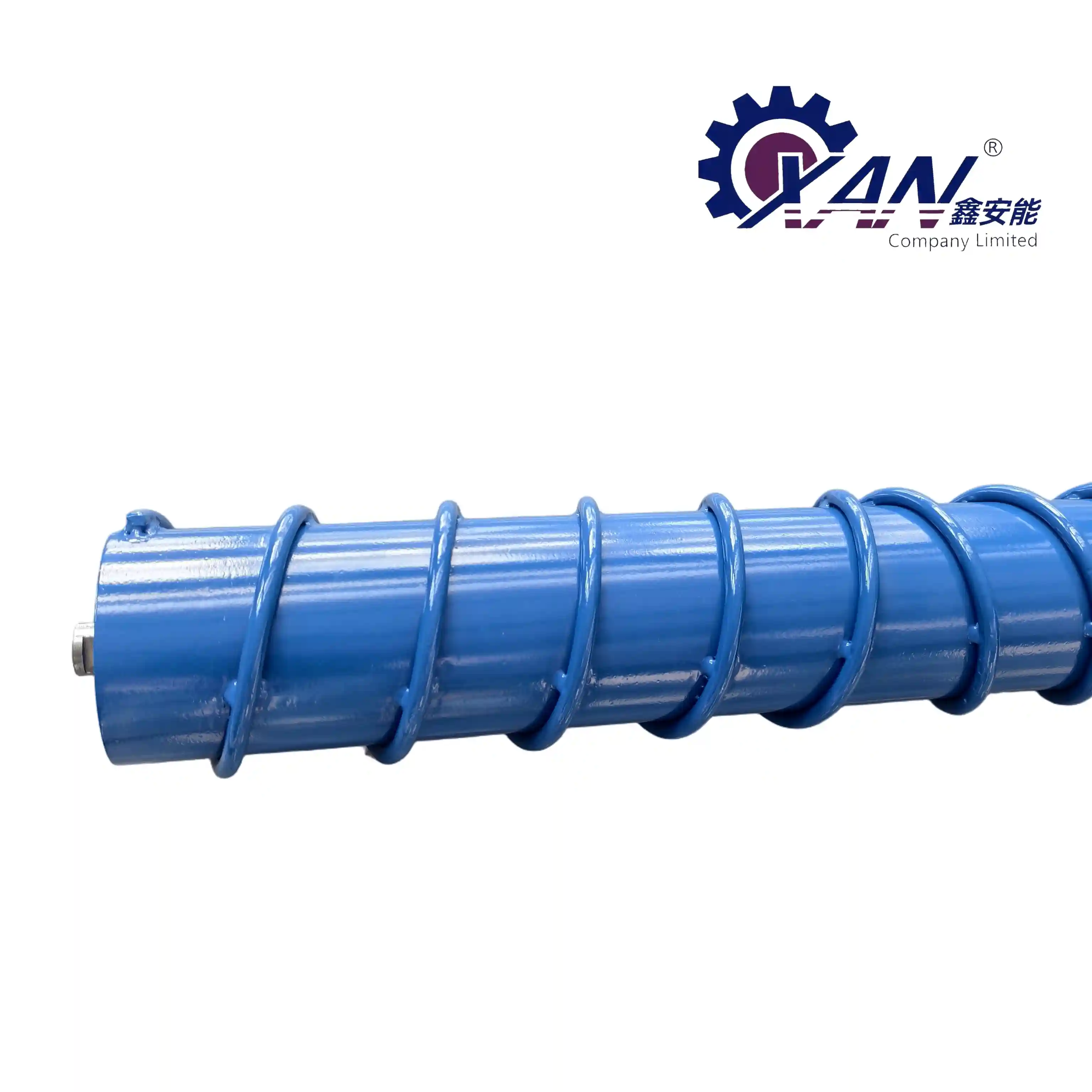

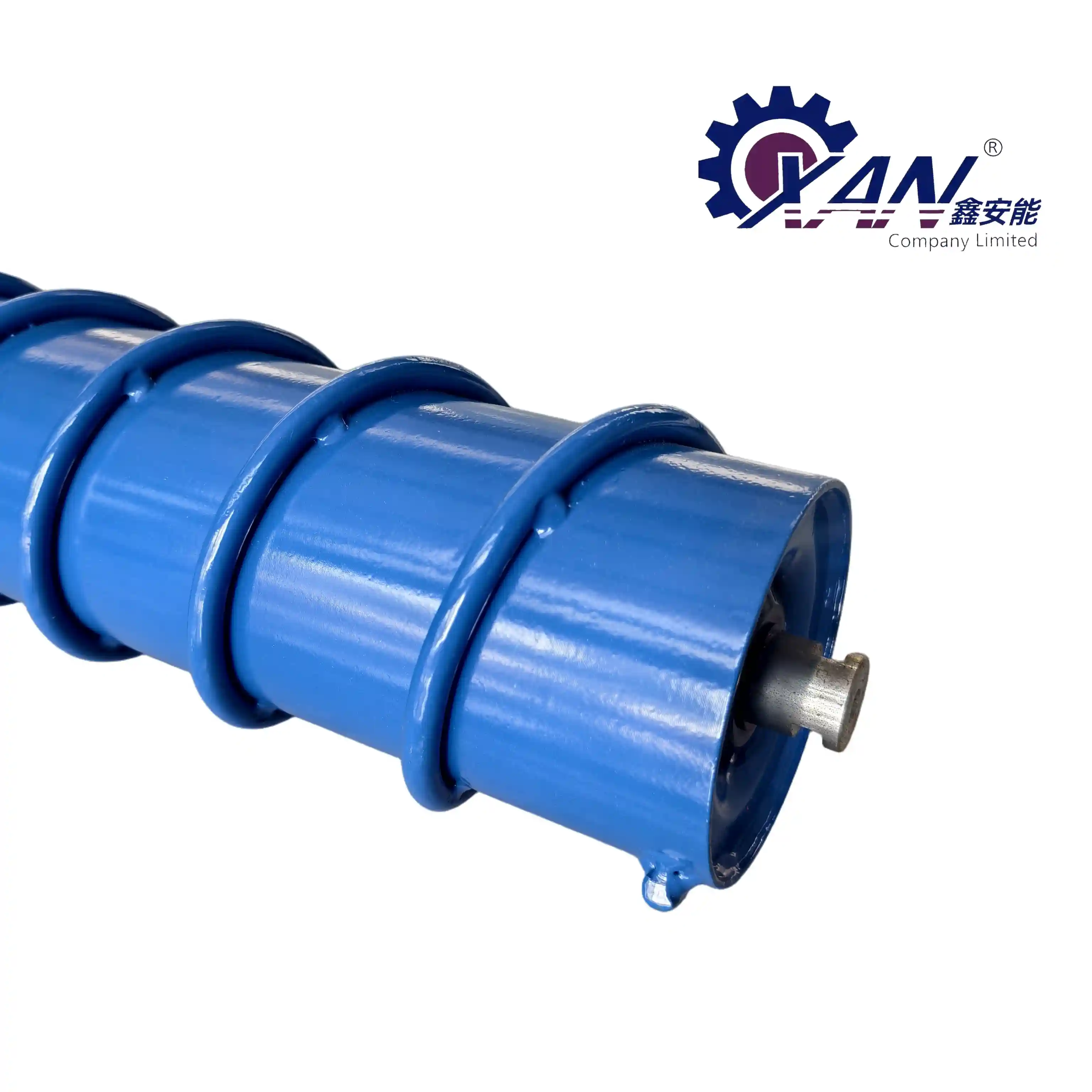

Steel Spiral Cleaning Idler

Spiral cleaning·Reduce sticky material·Protect the return section

The Steel Spiral Cleaning Idler produced by Hubei Xinanneng Conveyor Equipment Co., Ltd. is specially designed for the return section of the Conveyor Belt and aims to solve the problem of material adhesion on the surface of the return belt. Its core feature is that the roller surface is welded with left- and right-hand steel spiral structures. When the Idler rotates with the belt, a continuous relative displacement occurs between the spiral and the Conveyor Belt, thereby pushing the scraps, dust or wet materials adhering to the non-loading surface of the belt to both sides and allowing them to fall naturally.

This unique spiral cleaning mechanism can not only effectively prevent the roller body from losing roundness and increasing running resistance caused by material accumulation on the surface of the Idler, but can also significantly improve the deviation of the belt return section. The Idler has a solid structure and excellent wear resistance, which greatly reduces the work intensity of manual belt cleaning. It is an ideal supporting component to keep the conveyor system clean and extend the service life of the belt. It is widely used in industrial fields with a lot of dust or easy adhesion of materials such as coal, cement, and electricity.

Discover more - Made in China online store

Online display center: https://xanconveyor.en.made-in-china.com/