Trust across oceans: Xinanneng UK customized Ceramic Rubber Pulley was successfully delivered and highly praised

Recently, a batch of high-performance ceramic encapsulated Transmission Pulleys customized by Hubei Xinanneng Conveyor Equipment Co., Ltd. (hereinafter referred to as "Xinanneng") for a well-known British bulk material conveying system contractor successfully completed various rigorous inspections before leaving the factory and were officially packed and shipped. The smooth delivery of this batch of orders is not only a strong testimony that Xinanneng's products have once again entered the high-end market in Western Europe, but also marks that the company's technical strength in the fields of high-end customization and special-condition conveying accessories has reached the internationally advanced level.

英国客户定制滚筒

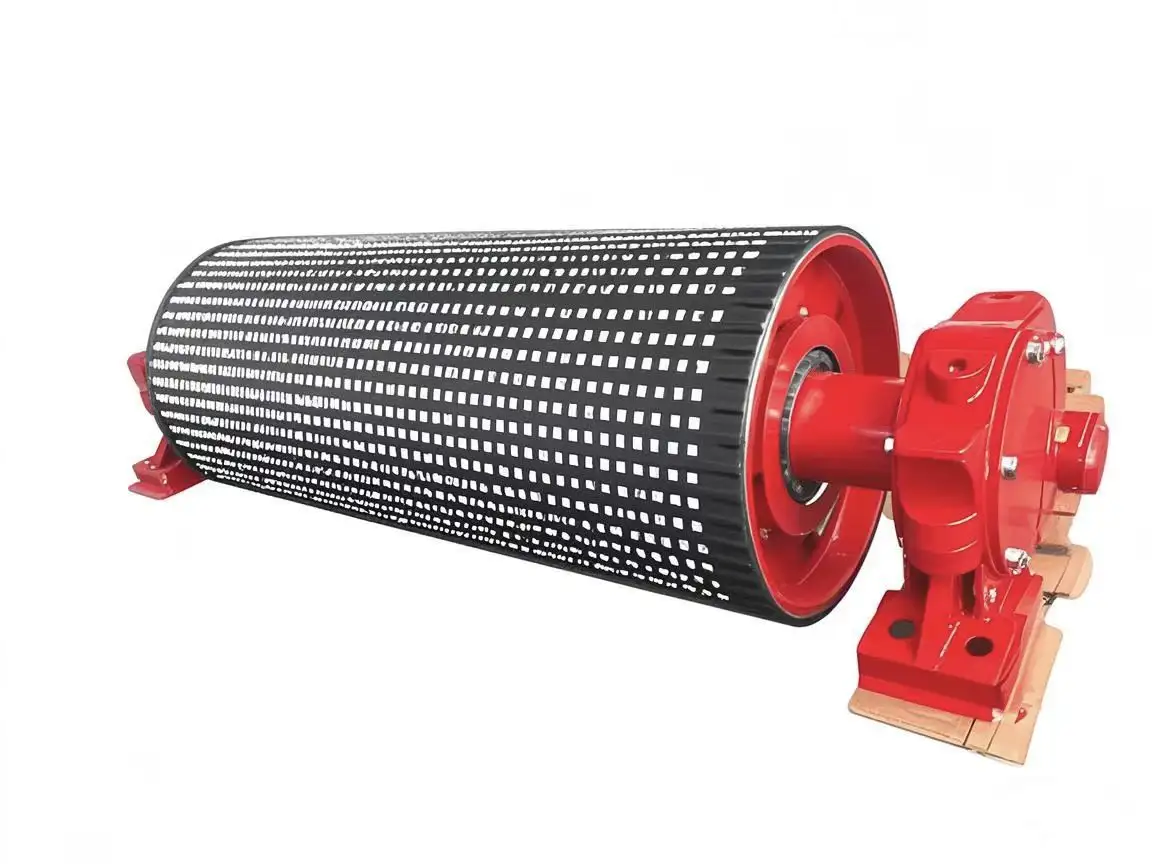

The Pulley purchased by the British customer will be directly used in the open-pit conveying system of the Liverpool Port and surrounding large-scale ore turnover centers. The port environment is extremely humid and the air contains a large amount of highly corrosive salt spray, which places almost stringent requirements on Pulley's anti-corrosion performance and transmission efficiency. In response to this special working condition, the Xinanneng technical team conducted in-depth research in the early design stage and decided to adopt a ceramic encapsulation solution of "extreme wear resistance + super grip" to cope with the wear challenges caused by long-term high-load operation. This solution not only effectively prevents belt slippage, but also significantly reduces the frequency of system maintenance.

英国客户定制滚筒1

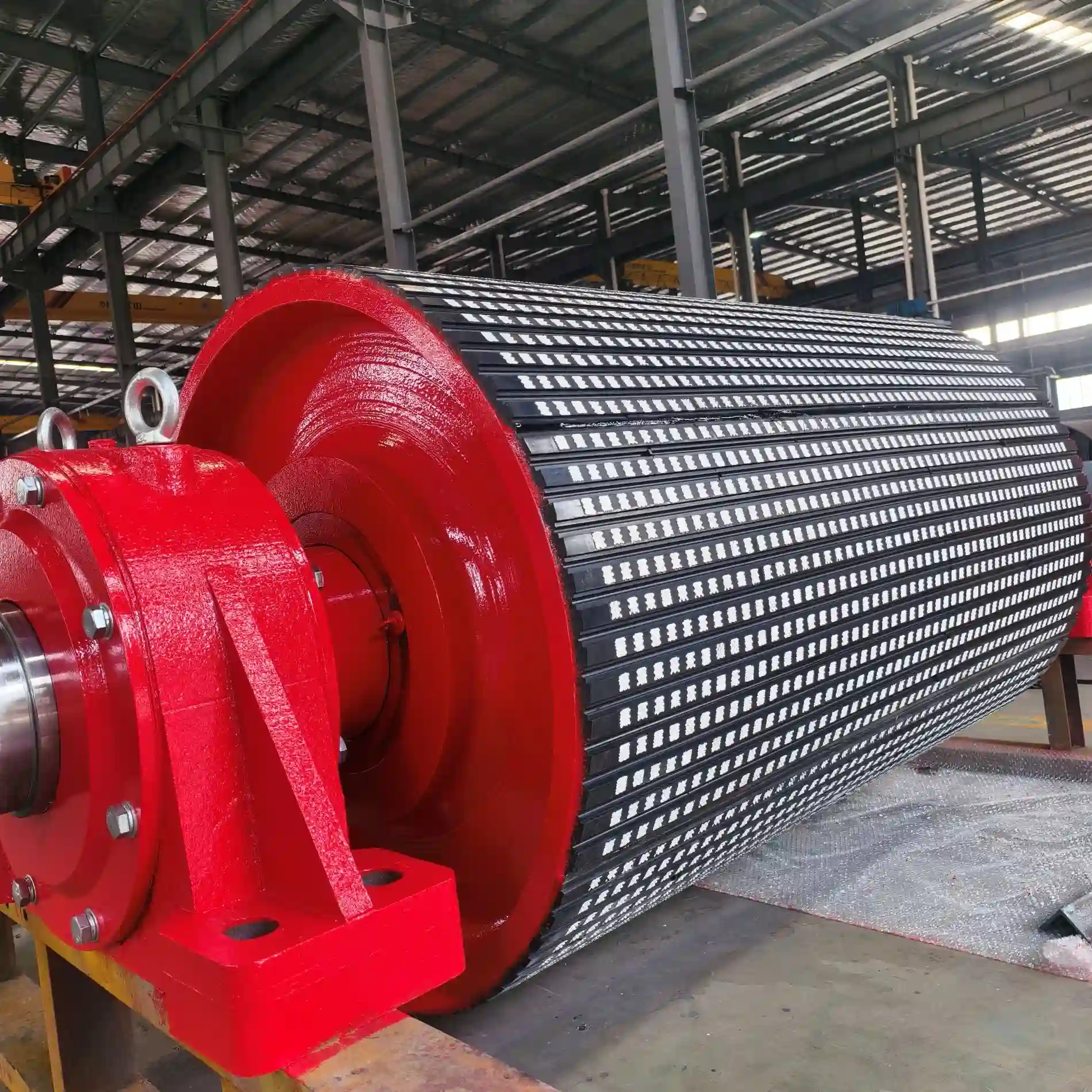

In the manufacturing process, this batch of Pulley bodies uses high-quality and high-strength Q345B low-alloy steel. We have introduced a CNC large-scale plate rolling machine to ensure the one-time molding accuracy of the Pulley cylinder, and the roundness error is far lower than the national standard (GB/T 10595). In terms of welding technology, advanced submerged arc automatic welding technology is used to not only ensure the depth and strength of the weld, but also ensure that every welding point is free of slag inclusions and pores through 100% ultrasonic flaw detection. In order to completely eliminate the residual internal stress generated during processing, all Pulleys have undergone strict high-temperature annealing heat treatment procedures, which lays a solid physical foundation for Pulley's long-term stable operation under harsh working conditions and effectively prevents cylinder deformation.

For the core encapsulation process, Xinanneng selected alumina ceramic blocks with a purity of up to 95%. These ceramic blocks are specially toughened to provide extremely high hardness and impact resistance. The ceramic block is embedded in a composite ceramic plate made of special wear-resistant rubber, and is firmly bonded to the surface of the cylinder using a cold vulcanization process. Compared with traditional diamond-shaped rubber encapsulation, the friction coefficient of ceramic encapsulation technology is increased by 2-3 times. Even in the case of extreme humidity, rain, or accumulation of sticky materials (such as wet coal slime or mineral sand), the raised particles on the ceramic surface can tightly grasp the Conveyor Belt like countless "micro-claws", providing constant traction and significantly reducing belt tension, thereby extending the service life of the entire Conveyor Belt.

In order to further improve the weather resistance of the product, this batch of Pulley has also put great effort into the surface treatment. We used sandblasting to remove rust to the highest standard of Sa2.5 level, with uniform surface roughness, and then immediately sprayed three layers of special heavy-duty anti-corrosion coatings: Epoxy zinc-rich primer, epoxy mica-iron intermediate coat and high-performance polyurethane topcoat. This composite coating system not only has extremely strong adhesion, but can also form a dense physical shielding layer to isolate oxygen and moisture in the port environment with high salt spray and high humidity. In addition, Pulley's bearing seat adopts Xinanneng's patented five-layer labyrinth seal structure, combined with heavy-duty spherical roller bearings from international first-line brands, to achieve excellent waterproof and dustproof performance.

英国客户定制滚筒2

In the final testing stage before leaving the factory, each Pulley undergoes static and dynamic balance calibrations that are more stringent than industry standards. At the simulated rated speed (up to 6m/s or above), the residual unbalance is controlled within the G16 level, and the vibration value during operation is almost negligible. In addition, we also conduct random peeling tests on the bonding strength of each ceramic plate to ensure that it will not fall off under extreme shear forces. This almost paranoid pursuit of details is the core competitiveness that enables Xinanneng to win the trust of overseas high-end customers.

The customer spoke highly of it after receiving the first batch of quality inspection reports and physical photos.: “The Ceramic Rubber Pulley provided by Xinanneng fully meets or even partially exceeds our expectations for high-end accessories in terms of welding details, uniformity of ceramic arrangement, and overall workmanship. This professionalism gives us confidence in our future long-term cooperation. ” Customers specifically mentioned our flexibility in non-standard customization solutions, which allows us to accurately adjust the shaft head size and keyway position according to the actual installation space on site.

英国客户定制滚筒3

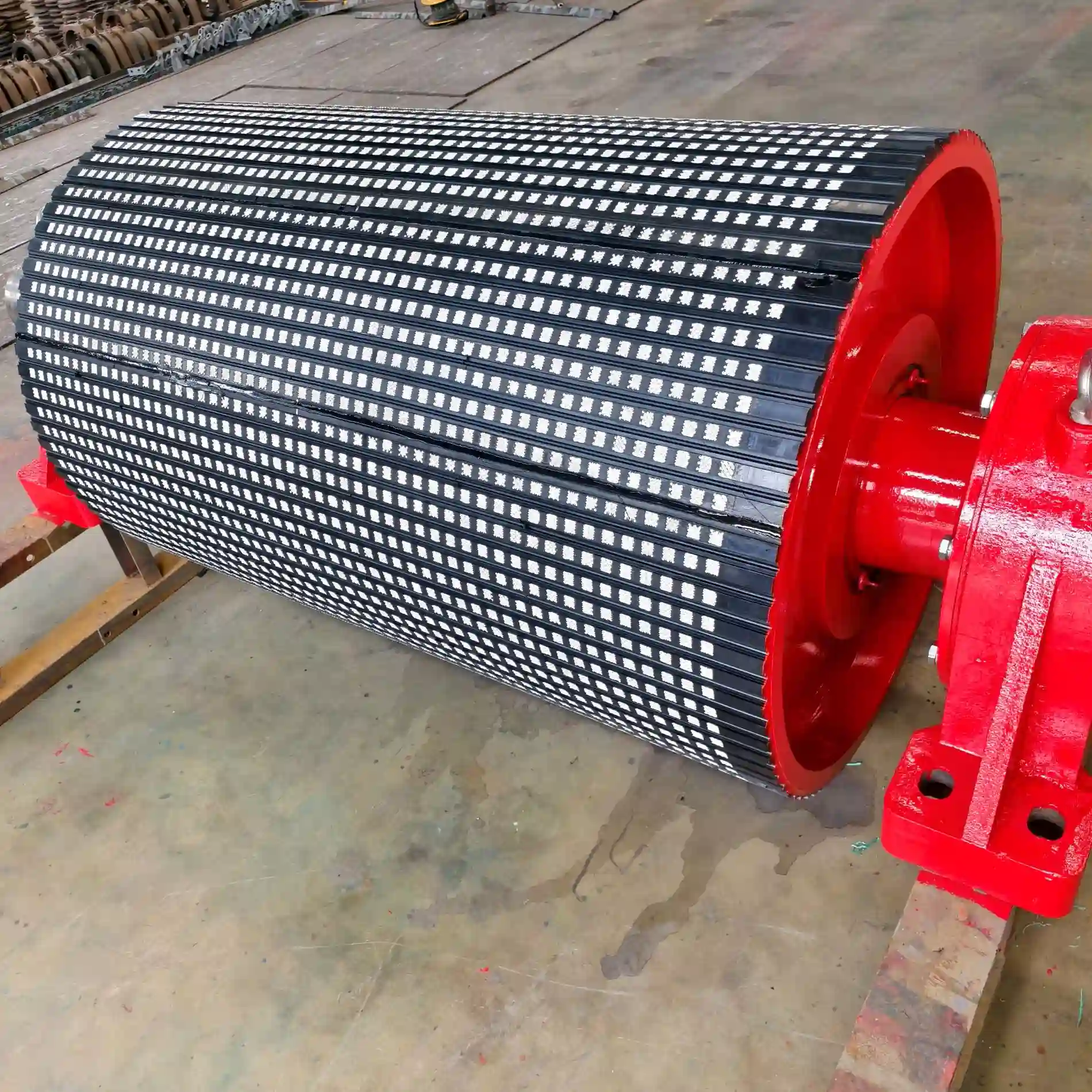

It is worth mentioning that in response to the special needs of the British project, Xinanneng also specially optimized Pulley's internal stiffener structure, which reduced the overall weight by about 12% while maintaining ultra-high mechanical strength. This not only effectively reduced the cost of ocean logistics, but also brought great convenience to the customer's on-site installation, hoisting and later maintenance and replacement. The company's technical engineers also provided detailed installation instructions, lubrication cycle recommendations and preventive maintenance plans to operators on site in the UK through video conferencing.

As global industries increasingly demand low-carbon, energy-saving and efficient operation, high-performance transmission components are becoming a mainstream trend in the market. Ceramic Rubber Pulley is gradually becoming a standard configuration in ports, mining, electric power and other industries due to its ultra-long service life (usually 3-5 times that of traditional rubber Pulley) and excellent power transmission efficiency. As a pioneer in this field, Xinanneng will continue to increase its R&D investment in high-performance elastomer materials, special ceramic formulas and automated precision manufacturing.

At present, these batches of Pulley have been successively delivered to the Liverpool project site in the UK and successfully passed the preliminary installation and commissioning. Xinanneng has always adhered to the global service concept of "win reputation with quality and promote development with innovation" and continues to delve into the international market. In the future, we plan to further expand our brand influence in high-end markets such as Western Europe and North America, and are committed to providing more reliable, durable and intelligent system component overall solutions for the global bulk material conveying industry, helping global customers achieve the goal of reducing costs and increasing efficiency.